Description

Seamless steel pipes are manufactured as complete singlepipes without any weld conforming to production method.At the beginning steps of manufacturing of seamless pipes isstarted in general by piercing, rolling or extrusion of round orsquare hot billets.

Hatboru sales Seamless Casing, Tubing, Drill Pipe and Line Pipeswith MTC certificates from stocks by importing from variousreliable international sources conforming to API 5CT/ 5D/ 5L/ 5B.

Casing Pipes

Casing pipes are manufactured byusing H40, J55, K55, N80-Q, M65, L80,C90, C95, T95, P110 and Q125 steelqualities from low to high mechanical strength conforming to API Standards.

By depending on the well depth andstring, outside diameters, wall thicknesses, steel material and thtreadtypes of casings are defined withhigh safety factors. Outside Diameter of Casing pipes varies from 4-1/2″(114,3 mm) fo 20″ (508 mm)

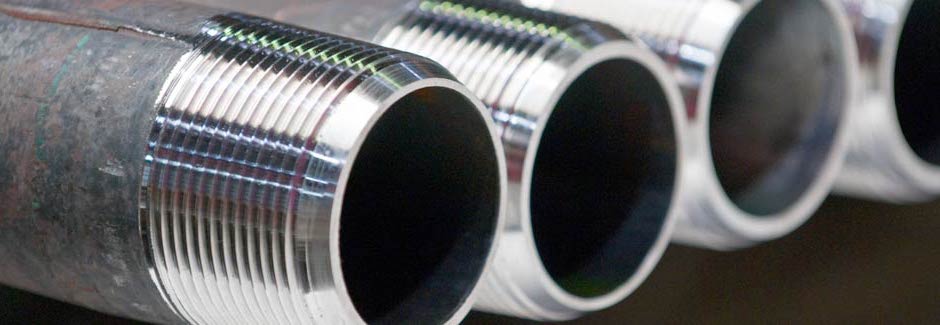

There are mainly three Standardthread types are available for casingconnections. These are STC (ShortThread Casing), LTC (Long ThreadCasing) and BTC (Buttress ThreadCasing) and they are cut conformingto API 5CT/5B standards. These casing pipes are manufactured for usein hot water, petroleum and naturalagas wells. In our workshop threadacutting, slotting and some coatings aoperations are performed according to API 5CT Standard.

Tubing Pipes

Outside Diameter of Tubing pipesvaries from 1,05″ (26,7 mm) to 4-1/2″(114,3 mm) according to API 5CT Standard. The same steel materials areused for manufaturing of tubing pipeswith casings.

Tubing pipes are manufacture as twotypes one non-upset (NU) and the other external upset (EU).

Drill Pipes

Drilling pipes from 27/” to 6″ OD with avarious steel materials and connection types are supplied form reliablesources by Hatboru.

© 2023 Hatboru. Her hakkı saklıdır.

© 2023 Hatboru. Her hakkı saklıdır.